Features of single-tier metal beds, their scope

In ancient times, metal beds were highly valued and successfully used in the formation of the interior. The generation of the second half of the 20th century also remembers models with comfortable backs and a soft springy mesh. Nowadays, single-tier metal beds are still relevant, only they have changed, they began to look brighter, more interesting. Today, numerous options for metal bedroom furniture can add sophistication, luxury, chic to your home interior or add a touch of romance. They combine perfectly with various textures - wood, glass, fabrics, stones. That is why such products are so appreciated by designers and are used in the design of premises in a wide variety of styles.

Features and Benefits

Today, interiors with metal furniture are held in high esteem by design masters. Rough, clumsy, outwardly sloppy products remained in the past. Any modern model is a work of art combining rigor, sophistication, and beauty.

Single-tier metal beds are in high demand not only for home furnishings. Manufacturers are also guided by public institutions: motels, hostels, recreation centers, military units. Such organizations need strong, durable, inexpensive metal products that can withstand high loads and difficult operating conditions. Their popularity is due to a wide range of advantages in comparison with similar products made of wood:

- Multifunctionality. Furniture can be located in rooms for various purposes. Thanks to the ergonomic design, it takes up little space.

- Long term of operation. The metal has high strength, does not change its characteristics over time. In addition, it resists deformation effects, the influence of insects and pests.

- Strength and stability. Metal is much stronger than wood, therefore, is able to withstand high loads. Due to this, iron structures are ideal for people with a lot of weight.

- Variety of options. Huge selection of models of any style, design. Given the scope of use, you can choose a classic or ultramodern version of furniture for both home and public institutions.

- Ease of use. Metal frames are ideally combined with various types of mattresses. The most convenient are orthopedic products that ensure spinal health, as well as a comfortable sleep. For public use, models made of foam rubber or cotton mattresses are suitable.

- Resistance to adverse effects and fire safety. Metal structures tolerate temperature changes without damage, which determines their use in conditions of high humidity indoors, outdoors.

- A high level of hygiene, microbes on such a surface do not multiply.

- Affordable cost. A wide price range allows you to purchase the product in accordance with your taste and financial capabilities. As a rule, budget models are inexpensive, unlike exclusive items with inserts made of leather, precious wood or forged elements.

- Easy care. Cleaning metal beds with detergents is not difficult, since the material does not absorb moisture, odors, and due to the protective coating it also resists corrosion processes very well.

The first iron beds appeared in ancient Egypt and Greece. Then metal furniture was not yet widespread and was an indicator of luxury, wealth, so it was available only to the upper class.

Classification by application

The universality of metal structures, their strength, durability, and also affordable cost make iron single-tier beds in demand in many areas of life. Manufacturers produce different types of products depending on the purpose:

- Furniture options for tourists, workers. They are used to equip dormitories, hostels, hotel complexes of economy class. The beds have an ergonomic design, attractive design, are equipped with a spring mattress, which provides a comfortable rest, healthy sleep.

- Models for builders. Convenient, compact, they are easily placed on a limited area of change houses or temporary buildings and are designed to relax after a shift. A number of products include a sliding design that allows you to adjust them in height. They are conveniently transported to other objects, and as unnecessary - stored in a warehouse.

- Medical metal beds. They are used to equip hospitals, dispensaries, and other medical institutions. A distinctive feature of the structures is the presence of a lifting mechanism, wheels, providing ease of movement of patients along the corridor. Medical models are equipped with a mechanical or electric drive, as well as adjustable backrests - this greatly facilitates the care of patients, especially bedridden patients. The base is divided into sections that can be raised, which is important when feeding or conducting medical procedures.

- Metal single-tier bed. It has a safe design due to the presence of three side backs and small dimensions. Widely used in kindergartens, orphanages, boarding schools.

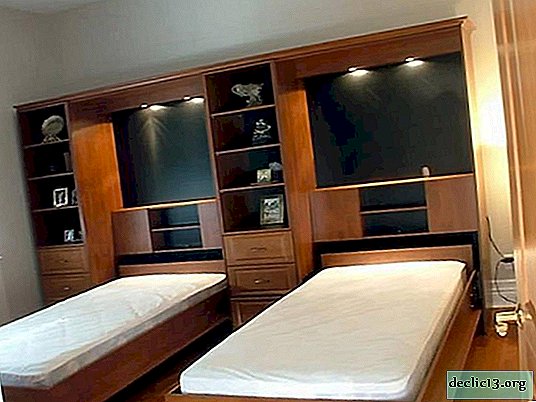

- Models for arranging children's and adult bedrooms in an apartment or private house. They are a serious competitor to wooden products, are durable, reliable metal frame, have different shapes and sizes. Furniture can be designed for one or two people, performed in various stylistic decisions. Children's single-tier beds are distinguished by an unusual design, stylish decor elements, and are equipped with orthopedic mattresses.

- Army beds. As a rule, these are budget models that are distinguished by simplicity of form, convenient design, and dimensions. The metal frame is made of high strength steel, complemented by shell or spring mesh. It provides a comfortable stay and a good sleep. The optimal dimensions are 180 x 200 cm.

When placing beds in living rooms, the dimensions of the furniture, their weight, and the cold metal texture should be considered.

For hostel

For hostel Army

Army For change house

For change house Medical

Medical For the bedroom

For the bedroom Children

ChildrenVarieties by method of manufacture

One of the criteria for choosing the best option for bedroom furniture made of metal is the method of its manufacture. Modern manufacturers choose pipes made of durable steel or a profile with a wall thickness of 1.5 mm as the material. The diameter can be varied taking into account design features. According to the method of manufacturing the beds are:

- Welded. Assume the creation of a frame by welding. Such models are characterized by high strength, simple concise forms, a minimum of decor and standard sizes. As a rule, they are equipped with a shell or spring net, although there are products supplemented with a base with wooden lamellas. Welded structures are used in rooms where, first of all, the strength and durability of a bed are evaluated, and only then its beauty and design.

- Factory made. This option is considered the most common. Products are assembled in the factory. The company offers customers a lineup in which there are several options that differ in size, color scheme. Production is put on stream, so each unit of production has a democratic value.

- Shod. Such products can be made in two ways: cold and hot. In the first case, factory equipment is used, and the process itself resembles stamping. The work is carried out by a broad specialist. In the second - the bed is made by hand and reflects the craftsmanship of a blacksmith. Products are distinguished by original design, custom design, higher cost.

The advantage of hand-made models is exclusivity, because such work is performed in a single copy, taking into account the wishes and preferences of the customer.

Factory

Factory Hand made

Hand made Welded

Welded Forged

ForgedMaterials and dimensions

Most single models have standard sizes of 160 x 200 cm and weigh an average of 35-40 kg. At the same time, the products withstand a load of 200 kilograms. A single-tier metal bed, reinforced with a bar frame, can be even heavier. This is due to the characteristics of the material from which the products are made:

- For the manufacture of the construction, pipes with a wall thickness of 1.5 mm or the same profile are used. They have a certain size standard: 40 x 20 or 40 x 40 mm. If you want to strengthen the frame, special jumpers are installed.

- Legs and backs are made of the same material as the base. Typically, such products are simple and affordable. Models combining metal and chipboard (glass, leather) are more valued. The latter are attached to the frame using bolted joints or a wedge mechanism.

- The reinforced metal single-tier bed provides a solid base made of a rod, which ensures the correct position of the mattress. Another option is a frame made from a corner to which an armored mesh is attached. The diameter of the cells is 5 x 5.5 x 10 and 10 x 10 cm. Such products are stiff and therefore not convenient enough. Softer, therefore, comfortable, springy bases are recognized.

Products for adults and children have significant differences, which are the number of backs. In the first case, there are only two, while in the second - as many as four, to ensure security.

Additional decor

When choosing a metal bed, the buyer pays attention not only to its practicality and functionality, but also to the design features. In most cases, metal beds may include the following decor:

- On the sides, on the back there are openwork forging elements. This visually facilitates the design, makes the product more airy and attractive.

- The frame, fully covered with textiles, for such models to determine the material of manufacture of the entire structure can only be on metal legs.

- The headboard made of glass or chipboard, covered with fabrics, leather.

Currently, single-tier beds made of metal are undergoing a rebirth. Thanks to a number of indisputable advantages - durability, reliability, multifunctionality, affordability - they are becoming increasingly popular. And innovative production technologies provide a convenient design, attractive design, which allows you to select furniture that best meets modern quality requirements and consumer demands.